Exploring Phenolic Ductwork Systems for Energy Efficiency

As the construction industry continues to prioritize energy efficiency and sustainability, pre-insulated duct systems like Kingspan KoolDuct offer a transformative approach to air distribution.

Article content provided by Kingspan.

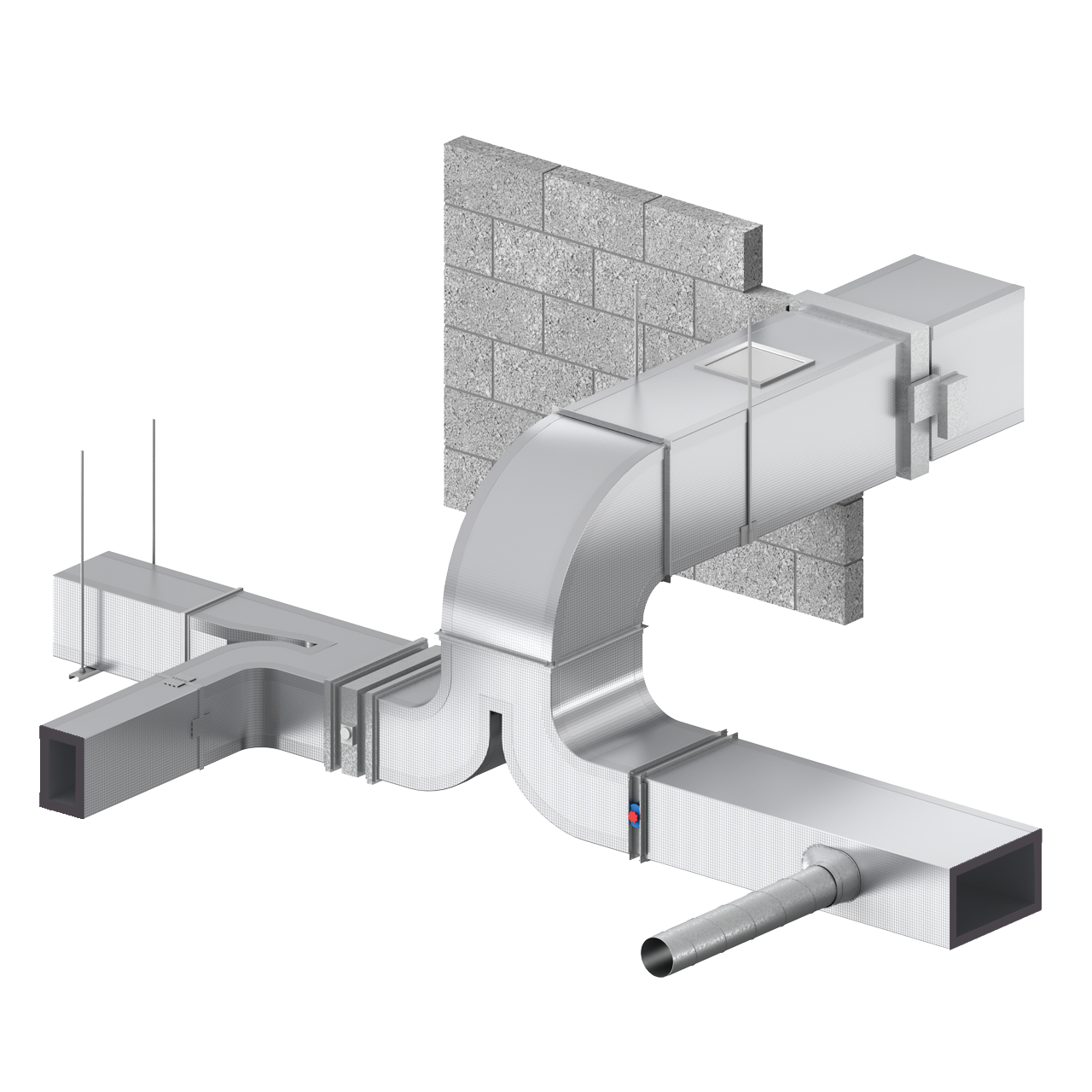

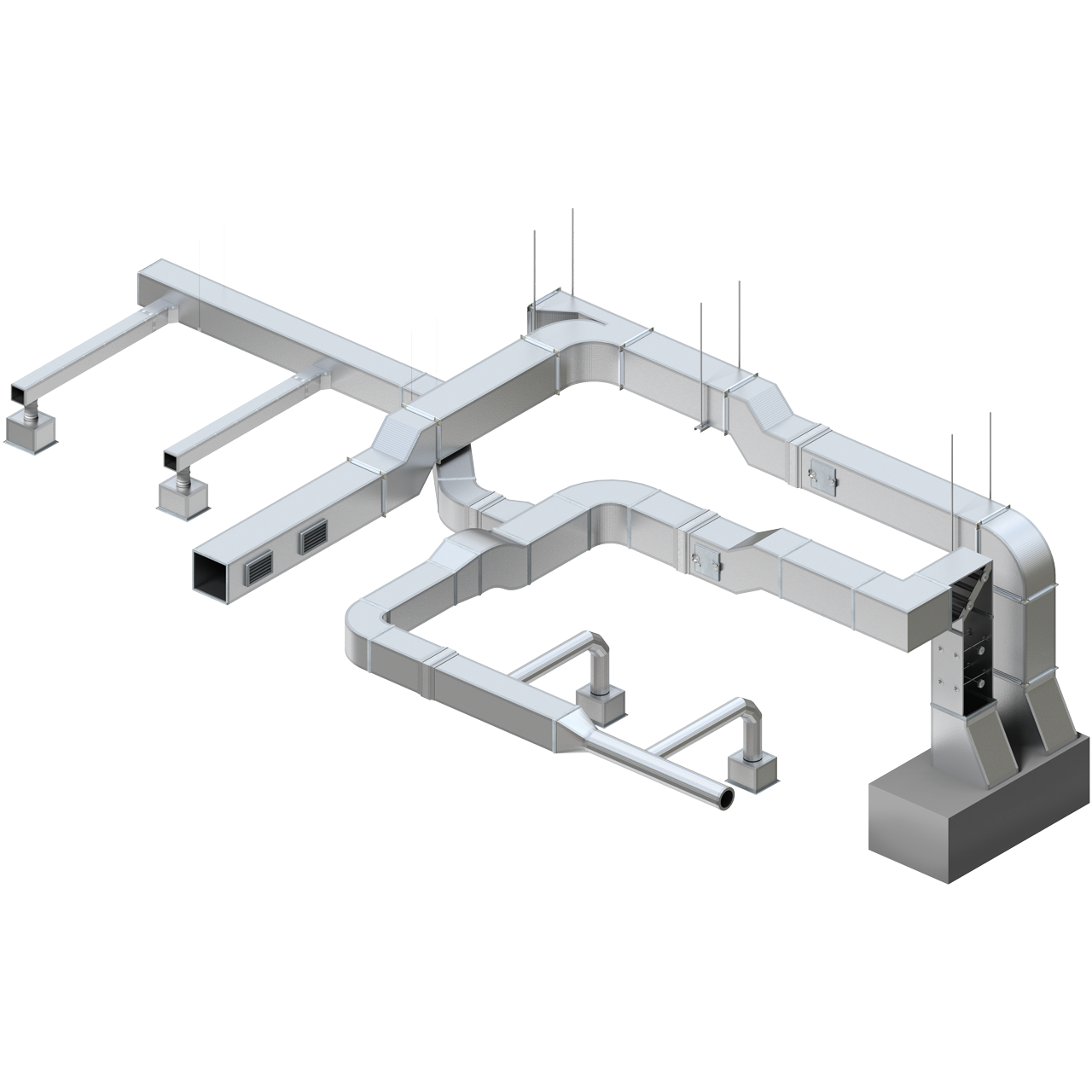

Kingspan KoolDuct is a pre-insulated ductwork system that replaces traditional sheet metal ducts wrapped in external insulation. It is constructed from rigid phenolic insulation panels faced with reinforced aluminum foil. These panels are fabricated into duct sections using a proprietary joining system that minimizes air leakage and maximizes thermal performance.

Unlike conventional systems, KoolDuct integrates insulation directly into the duct wall, eliminating the need for secondary insulation trades and reducing the overall duct profile. The result is a lightweight, high-performance system that meets or exceeds modern energy codes.

Superior Energy Efficiency

One of KoolDuct’s most compelling advantages is its contribution to HVAC energy efficiency. The phenolic core has an exceptionally low thermal conductivity—0.019 W/m·K—resulting in a high R-value of over R6.8 per inch, exceeding fiberglass or elastomeric insulation

Additionally, KoolDuct’s joining system is designed to achieve low air leakage rates, often outperforming SMACNA Class 3 standards. Reduced leakage means less fan energy is required to maintain airflow, and conditioned air reaches its destination more efficiently. This translates to lower energy bills and improved occupant comfort.

KoolDuct panels are available in range of insulation values, R6 to R12, achieving compliance with ASHRAE 90.1, IECC, and other energy codes, making them an ideal choice for projects targeting LEED certification or net-zero energy goals.

Installation and Labor Savings

From a contractor’s perspective, KoolDuct offers significant labor and logistical benefits. The system is up to 72% lighter than traditional insulated sheet metal ductwork, which simplifies handling, reduces structural load, and speeds up installation.

Duct sections can be prefabricated offsite or assembled & modified onsite using Kingspan’s fabrication tools and training. This flexibility allows contractors to adapt to project schedules and site conditions while maintaining quality control. Because insulation is built-in, there’s no need to coordinate with separate insulation crews, reducing trade overlap and potential delays.

Design Flexibility in Tight Spaces

KoolDuct’s slim insulation profile, starting at 7/8”, is a game-changer for architects and engineers working in space-constrained environments. The thinner profile allows the system to be routed through tighter ceiling voids and mechanical chases, freeing up valuable ceiling space for other services.

This makes KoolDuct particularly well-suited for applications such as hospitals, schools, data centers, and retrofits—anywhere where space, speed, and performance are at a premium.

Indoor Air Quality and Sustainability

In addition to energy performance, KoolDuct supports healthy indoor environments. The phenolic insulation is non-fibrous, non-wicking, and resistant to microbial growth, contributing to better indoor air quality and occupant health.

From a sustainability standpoint, duct systems utilizing KoolDuct can receive points towards achieving credits in the LEED® Building rating systems developed by United States Green Building Council.

Code Compliance and Fire Safety

In addition to its energy and installation benefits, KoolDuct stands out for its rigorous compliance with fire safety standards, most notably UL 181, the industry benchmark for air duct systems.

UL 181 is a safety standard developed by Underwriters Laboratories that evaluates the fire resistance, smoke development, and structural integrity of air ducts and connectors. KoolDuct is a UL 181 Listed Class 1 Air Duct, meaning it has achieved a flame spread and smoke development of less than 25/50. Making KoolDuct code compliant for use within the building envelope.

Phenolic Insulation in Outdoor Duct Systems

The benefits of phenolic insulation extend beyond interior applications. Outdoor-rated phenolic duct systems such as Thermaduct®, Pro-R®, Tuff Duct®, and Dual-Tech® are powered by the same Kingspan KoolDuct core to deliver high-performance insulation for air distribution in exterior environments.

These systems are engineered with UV-resistant, weatherproof cladding and sealed joints to withstand harsh outdoor conditions while maintaining low thermal conductivity and high R-values to prevent condensation. Phenolic insulation’s closed-cell structure provides excellent moisture resistance, reducing the risk of degradation over time. Many of these systems carry 10+ year extended warranty, a testament to the longevity provided by KoolDuct’s durability & performance in rugged environments.

Real-World Results

A detailed case study was conducted of a retrofit in mid-sized healthcare facility, the mechanical contractor reported a 21% reduction in installation costs using KoolDuct compared to traditional ductwork. The lighter weight allowed for easier handling in tight ceiling spaces, and the integrated insulation eliminated the need for follow-up trades. Energy modeling projected a 20% reduction in HVAC energy consumption due to improved thermal performance and reduced leakage.

Conclusion

As the HVAC industry evolves to meet the demands of high-performance buildings, ductwork must evolve with it. Kingspan KoolDuct offers a compelling alternative to traditional systems, combining energy efficiency, installation speed, code compliance, and design flexibility in a single solution. For mechanical engineers and HVAC contractors looking to deliver value on every project, KoolDuct is more than just a duct system—it’s a smarter way to build.

Please view the entire line of Kingspan products here.

Have a question for Kingspan? Contact Kingspan here.

Manufacturer of pre-insulated ductwork panels, ductwork insulation, ancillary components to allow ductwork manufacture.

Jul 10, 2025 — Products & Services Update