Check Your Duct Liner Specs for Fire Performance

Recent NAIMA testing shows failure of elastomeric duct liner products. Read the complete study results here.

Article content provided by Johns Manville.

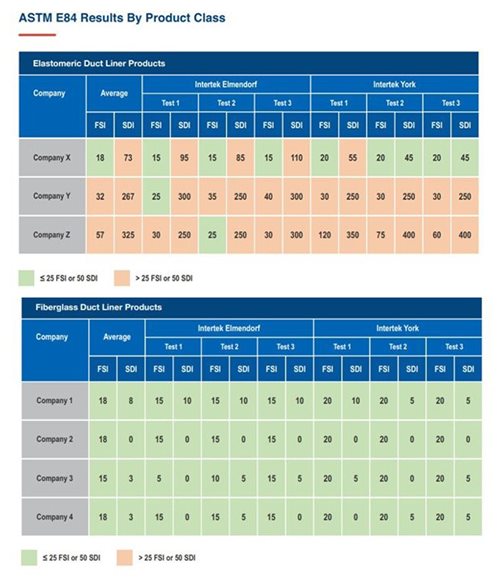

NAIMA performed independent testing on fiberglass and elastomeric duct insulation products since there are stringent FSI and SDI limits for those products located in plenum spaces, and here are the results.

The purpose of this test was to observe the flame spread along a sample to determine the relative burning behavior of the material. There are several ASTM E84 references in the International Mechanical Code (IMC) that set limits to the Flame Spread Index (FSI) and Smoke Developed Index (SDI) in specific applications. Most relevant for this study, the IMC sets stringent FSI and SDI limits for duct insulation products located in plenum spaces to ensure occupant safety from dangerous fire spread and smoke in the event of fire.

NAIMA developed a plan to systematically conduct third-party testing of both elastomeric and fiberglass duct liner products at multiple Intertek Laboratories. The engagement of a third-party test laboratory as a part of this test program ensures that the ASTM E84 and E2231 procedures are followed without individual manufacturers guiding product selection or configuration of the test apparatus. The results of the test program are listed below and show a systemic issue with the performance of elastomeric products.

The results of this study are not intended to make claims on individual elastomeric products, but to display the issue at large. However, company claims should be investigated further based on the performance seen in this test program. View the study in its entirety here.

Actions Designers and Specifiers Can Take Today

- Request third-party ASTM E84 testing report for the specific products. The testing program found that, as a product category, elastomeric products with published flame spread index (FSI) and smoke developed index (SDI) values of 25 and 50 far exceeded claimed performance. While some products may meet 25 FSI and 50 SDI, the values included on product data sheets for elastomeric products were not in line with actual product performance. During engagement with manufacturers to discuss participation in the program, elastomeric manufacturers did not provide ASTM E84 test reports to corroborate their published data sheet claims for fire performance.

- Revisit your standards specifications if they include elastomeric duct liner products. If you have standard specifications for elastomeric duct liner products, it may be worthwhile to call out specific products that you have obtained ASTM E84 reports for or remove elastomeric from the standard specification until more information is provided.

Visit the Johns Manville website.

Have a question for Johns Manville? Contact Johns Manville here.

Johns Manville supports contractors with productivity-enhancing and performance-enhancing mechanical products, including duct, pipe, and building insulations.

Sep 30, 2024 — Products & Services Update

Latest Articles

Feb 17, 2026 - The Milwaukee M18™ Compact 1-Ton Chain Hoist w/ One-Key™ is a battery-powered chain hoist that provides the ability to lift one metric ton (2,204 lbs) at 20’ lift height.

Feb 17, 2026 - Every workplace faces some degree of risk in their daily operations. Part of your role as a business owner is to communicate why risk management helps with employee safety.

Feb 17, 2026 - Season 2 of The Power of Construction is here—featuring bold conversations with the pioneers shaping construction’s future.