Optimizing Sheet Metal Assembly - Insights from Liz Fong

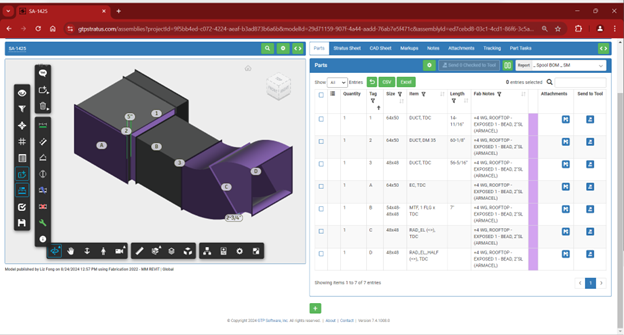

Liz Fong, SMACNA’s 2025 Innovator of the Year & Operations Integration Manager at MacDonald-Miller, shares how she and her team use Stratus to modernize duct assembly workflows and push the boundaries of what’s possible in sheet metal.

Article content provided by Stratus.

Article content provided by Stratus.

With a deep background in construction tech and sheet metal, Liz brings nearly 2 years of experience implementing Stratus across trades and teams. Her initial Stratus implementation focus? Optimizing duct assembly.

At MacDonald-Miller, over 75% of model-based duct fabrication is assembled in the shop—resulting in more than 44,000 pieces of duct getting prefabricated into 16,000 assemblies each year.

Key gains:

- Dedicated assembly stations in our controlled shop environment—placed between fabrication and shipping—streamline material flow and boost ergonomics and jointing productivity.

- Shop-floor pre-assembly of ductwork reduces on-site jointing and material handling, speeding up field installation.

“Reducing the number of joints that need to be made on-site eases the installation burden for our field teams.” — Liz Fong

MacDonald-Miller first went paperless in 2018 using iPads and PDFs via SharePoint, but true digital transformation began with Stratus.

With Stratus:

- No PDFs required for Field Review processes or Shop Assembly - Just live, integrated, model-based workflows.

- Improved communication between VDC, Field and Shop Teams due to increased visibility and accessibility.

- Issues/Errors are easily identified ahead of fabrication due to increased visibility and accessibility.

“We estimate this equates to about 2,800 detailing hours saved annually,” Liz explains.

Liz’s Top 5 Tips for Maximizing Stratus for Duct Assembly

- Define Assemblies Simply

Assign every part—whether multi- or single-piece—to an assembly for easier tracking, installation, and model annotation. - Build Direct Links

Use direct URLs to Stratus views to skip QR code navigation and save time. - Use Purposeful Coloring

Color-code parts to visually distinguish components at a glance. - Simplify Connector Info

Consolidate connector details into a single field to reduce cognitive load. - Make Key Data Easy to Find

Keep essential info front and center to avoid digging through properties.

Contact Stratus to request a demo.

Stratus is a cloud-based software platform that revolutionizes MEP fabrication and construction management by seamlessly integrating CAD software like Revit and AutoCAD with manufacturing tools to reduce errors and boost efficiency. By leveraging digital models for precision fabrication and enabling real-time collaboration, Stratus enhances communication among teams and ensures accurate project tracking.

Jun 11, 2025 — Products & Services Update

Latest Articles

Feb 17, 2026 - The Milwaukee M18™ Compact 1-Ton Chain Hoist w/ One-Key™ is a battery-powered chain hoist that provides the ability to lift one metric ton (2,204 lbs) at 20’ lift height.

Feb 17, 2026 - Every workplace faces some degree of risk in their daily operations. Part of your role as a business owner is to communicate why risk management helps with employee safety.

Feb 17, 2026 - Season 2 of The Power of Construction is here—featuring bold conversations with the pioneers shaping construction’s future.