More Than Just Another Office Project

SMACNA member Dee Cramer was hired to perform HVAC construction on a corporate campus built to harmonize with the environment.

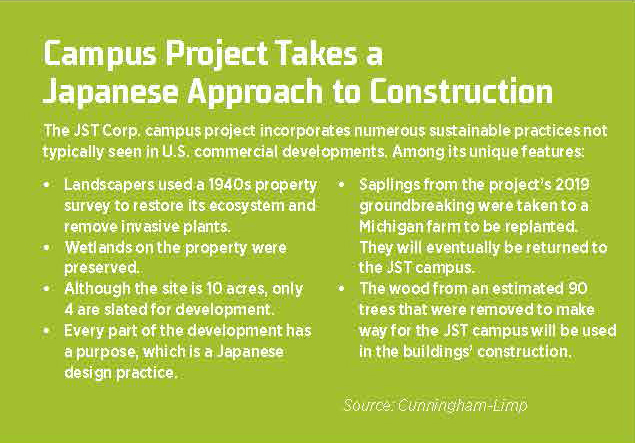

Sustainable. Eco-friendly. Green. The Farmington Hills, Michigan, campus of Japan Solderless Terminals (JST) Corp. was designed to go beyond typical labels. The 10-acre, six-building property takes in its surroundings in a way unlike most corporate campuses.

Instead of replacing native vegetation with grass, it preserves and expands the plants. As opposed to buildings that feature huge glass panes, JST’s structures make extensive use of natural materials like wood and stone. Drywall is forbidden. Paint is banished. And synthetic, commercial carpeting is nowhere to be found.

It’s not what you might expect for a multinational manufacturer of electrical connectors used in industries such as automotive and HVAC. But it’s keeping in line with Osaka, Japan-based JST’s Asian approach to design, which aims to create spaces in harmony with the environment and that respect nature.

Cunningham-Limp, the project’s Construction Manager, calls it “the most holistically sustainable project ever seen in Michigan.” When completed, the JST campus will encompass six buildings: a test lab, sales center, engineering center, annex, center circle loop, and a “tree nest.” The buildings will not disrupt the animals or natural habitats of the heavily wooded site, which sits in the heart of metropolitan Detroit.

DEE CRAMER AWARDED PROJECT

Cunningham-Limp awarded SMACNA member Dee Cramer of Holly, Michigan, a $3-million contract in 2021 to handle HVAC construction for this holistic sustainable building, including duct fabrication and installation, at the campus test lab. The lab, which is an evaluation site for the critical electronic components that JST manufactures, was the first campus building that was erected.

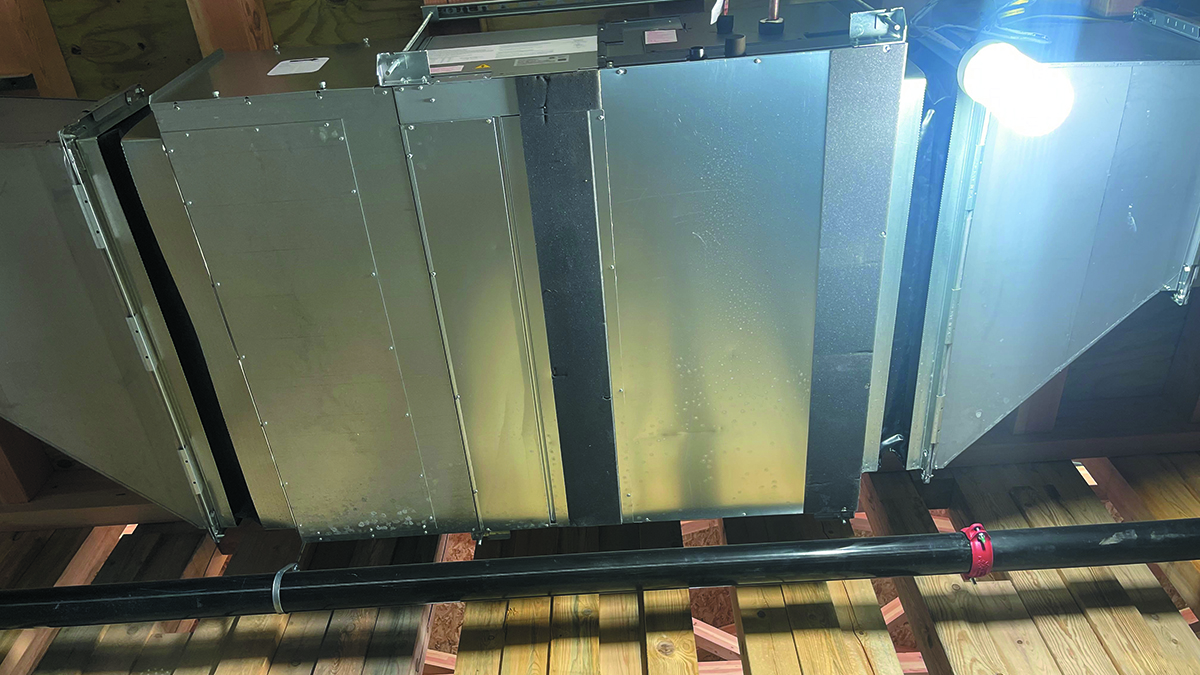

Aaron Montgomery, Dee Cramer Project Manager, explained that his company’s work began where the geothermal system tied into the piping (installed by a subcontractor) and the HVAC system. The piping entering the lab connects to 30 ducted fan coil units and numerous branch boxes that help condition the lab’s corridors. “Piping goes into four condensers and then numerous heat exchangers,” Montgomery says. “There’s also dedicated outdoor air systems (DOAS) — three of them just in the test lab alone.”

The test lab used approximately 23,000 pounds of internally lined duct, all of which was fabricated at Dee Cramer’s Wixom, Michigan, facility, about 11 miles from the jobsite. Most of the ductwork was rectangular, with some spiral.

AN EDUCATIONAL EXPERIENCE

JST’s commitment to sustainable construction presented a learning curve for Dee Cramer and some of the other contractors involved. “It was a bit of a struggle on everybody's end because it's a timber-frame building,” Montgomery says. “There's not much timber-frame construction and carpentry experience here in the local Detroit area. It was such a trying process sometimes.”

Nick Seraphinoff, the Vice President of Project Management at Dee Cramer, says the use of timber-frame construction made the project more complicated. “It affected the types of fasteners and hangers that we could use, as well as the coordination with other trades,” he says.

The lab was completed in 2023. Officials with Cunningham-Limp and JST were pleased with Dee Cramer’s work. The contractor was hired to perform the HVAC work on four other campus buildings, bringing the total contracts to around $7 million in value. Dee Cramer’s work on the sales building is now underway.

The lab was completed in 2023. Officials with Cunningham-Limp and JST were pleased with Dee Cramer’s work. The contractor was hired to perform the HVAC work on four other campus buildings, bringing the total contracts to around $7 million in value. Dee Cramer’s work on the sales building is now underway.

Published: October 21, 2025

IN THIS ISSUE

A Year of Legislative Wins

How SMACNA’s Government Affairs department is advocating for members in 2025.

Big Build, Bigger Challenge

Welsch Heating and Cooling delivers energy efficiency and architectural style on one of St. Louis’s largest residential projects.

Chapter Spotlight: PHILADELPHIA - How a Century-Old Association is Forging New Leaders

SMCA is cultivating young leadership, strengthening labor ties and expanding educational programs to keep Philadelphia’s sheet metal industry strong, sustainable and future-ready.

Construction Tax Planning Under the One Big Beautiful Bill

The One Big Beautiful Bill Act (OBBBA), a sweeping 2025 tax reform package, introduces wide-ranging changes to federal tax policy. While it may appear broadly applicable across industries, its impact on construction is direct and substantial.

Driving Fabrication Innovation

Dynamic Systems thrives by delivering mechanical construction precision through advanced technologies and streamlined digital workflows.

Fifth Circuit Finds NLRB Structure Likely Unconstitutional

On Aug. 19, the U.S. Court of Appeals for the Fifth Circuit halted unfair labor practice proceedings against three employers, most notably SpaceX, before the National Labor Relations Board (NLRB).

How Do Contractors Turn Policy Into Progress?

Contractors and SMACNA staff know advocacy matters. When members get involved, our voices are heard and we shape policies that protect and grow our industry.

How Getting Involved Can Make a Big Difference

SMACNA's President discusses the importance of engaging with lawmakers and reflects on his term.

Latest SMACNA Publications

Explore SMACNA’s latest publications with insights on BIM and IP, practical resources to help contractors improve projects, protect their businesses, and stay ahead.

More Than Just Another Office Project

SMACNA member Dee Cramer was hired to perform HVAC construction on a corporate campus built to harmonize with the environment.

Shining Symbol of Strength

Copper walls by General Sheet Metal define IBEW 48’s hall.

SMACNA’s Legacy of Government Relations

SMACNA's CEO discusses the significant role government relations have always played at SMACNA and details his own interaction with our team on the Hill.

The Majority of SMACNA Members Need a CTO

It’s no secret that our industry has seen a rapid digital transformation over the past two decades. From BIM and ERP systems to robotic layout and cloud project management, today’s contractors and fabricators have access to powerful tools.

Welcome New SMACNA Members