Architectural: Working in the Red Zone

A Michigan contractor scored when the company made and installed a hotel's architectural panels just in time for the 2024 NFL draft.

Running out the clock wasn’t an option when SMACNA member Liberty Sheet Metal won a bid to put new architectural panels on a Detroit hotel.

Running out the clock wasn’t an option when SMACNA member Liberty Sheet Metal won a bid to put new architectural panels on a Detroit hotel.

The downtown Courtyard Marriott would be packed with guests in town for the 2024 NFL draft. Liberty workers would have just weeks — without timeouts or delays — to fabricate and install panels for the hotel's front entrance. The new facade was part of a $9.5 million renovation of the 260-room property.

The draft was one of the biggest events to hit the Motor City in recent memory. It wasn’t just an announcement of players and teams for the upcoming season. It was a multi-day celebration of America’s favorite sport, with interactive exhibits, free concerts and the chance to get player autographs and see the famous Vince Lombardi Trophy. Hundreds of thousands of fans from across the country were expected to attend the 2024 draft.

Higley Construction, the project’s Ohio-based general contractor, awarded Liberty the $250,000 contract in December 2023. The draft was taking place April 25-27, 2024. But because the hotel entrance had to be rebuilt before the panels could be installed, Liberty couldn’t start putting them in place until March. That gave the company only a few weeks to complete its work.

A 100% Architectural Company

Based in a rural part of southeastern Michigan, Liberty Sheet Metal is a 100% architectural contractor that’s been in business more than 25 years. It specializes in aluminum composite panels; metal walls, siding and roofing; and custom architectural designs. Its project list includes a nearby high school, apartment complexes, the University of Michigan and a major Mercedes-Benz research facility.

Justin Becker, Liberty’s Director of Estimating and Project Management, says the short time frame, plus the high profile of the NFL draft, made it different.

“This was an interesting project,” Becker says. “We were selected because of our knowledge and our experience. We definitely had a budget that we had to maintain, but they were most concerned about scheduling and timing and the unique materials on the facade.”

The hotel’s new entrance features about 2,000 square feet of panels from manufacturers such as Longboard, Reynobond and Knight Wall. They’re made from 0.125-inch aluminum and 4 mm composite aluminum, finished in colors such as black and Light National Walnut. The entrance has warm tones of wood that contrast with silver metal highlights.

Fabrication work took place at Liberty’s 40,000-square-foot sheet metal shop, located about an hour from Detroit. Becker says they ran into an issue securing the mineral wool used to insulate the metal panels.

“Back in January of 2024, there was a huge mineral wool shortage,” Becker recalls. “It was really hard to get. I was making calls left and right to get the mineral wool. We had to ‘steal’ it from other jobs and make deals with other people to get enough for this job.”Trucks brought panels from the shop twice a week. Liberty’s Project Foreman Frank Vallejo supervised the work.

With all trades working in a tight area with the NFL draft deadline looming, Becker expected the project work to get hectic.

“I've never had so many meetings and so much coordination for what I would consider a relatively small job,” he says. “But because of that, we navigated and mitigated any disasters. Everything had to be thought through. So we would sit in meetings to figure out ‘How do we navigate around this issue?’ And I was like, ‘Well, we can do this, this and that with what we’ve got.’ And then, boom. ‘OK, let’s do that.’”

Becker says Liberty employees never forgot that they were working on a high-profile job that would make an impression on people from across the country.

“That was kind of in the back of our minds the whole time,” he says.

Liberty finished its work in early April, a few weeks before the draft. Becker went to the event as a fan and to check out his company’s work.

“I walked right past the hotel. It was open and people were just walking through,” he says. “I was like, ‘Man, if you were here two months ago. You should have seen the chaos that was going on.’”

Becker says Higley was happy with Liberty’s work on the hotel. And Aaron Paczkowski, the Higley executive on the project, was good to work with, he adds.

“We had developed a great relationship with the general contractor,” Becker says. “So we're getting more work with them, I think, because of our performance on this project.”

Published: April 30, 2025

IN THIS ISSUE

A Hub for Cutting-Edge Technology & Collaboration

Attendees Get Hands-On During the Sheet Metal JATC Local 105 Tour at the 2025 MEP Innovation Conference.

Architectural: Working in the Red Zone

A Michigan contractor scored when the company made and installed a hotel's architectural panels just in time for the 2024 NFL draft.

HVAC: Understanding Refrigerant Transitions

What HVAC contractors need to know about these important changes.

Industrial: Aiming High

Matherly Mechanical’s ventilation project at an Oklahoma City Air Force base was critical to ensuring that work servicing military aircraft continued uninterrupted.

JATCs Assess the Impact of President Trump’s Executive Order Ending Affirmative Action and DEI Programs

On Jan. 21, 2025, President Trump signed Executive Order 14173, “Ending Illegal Discrimination and Restoring Merit-Based Opportunity” (the “EO”).

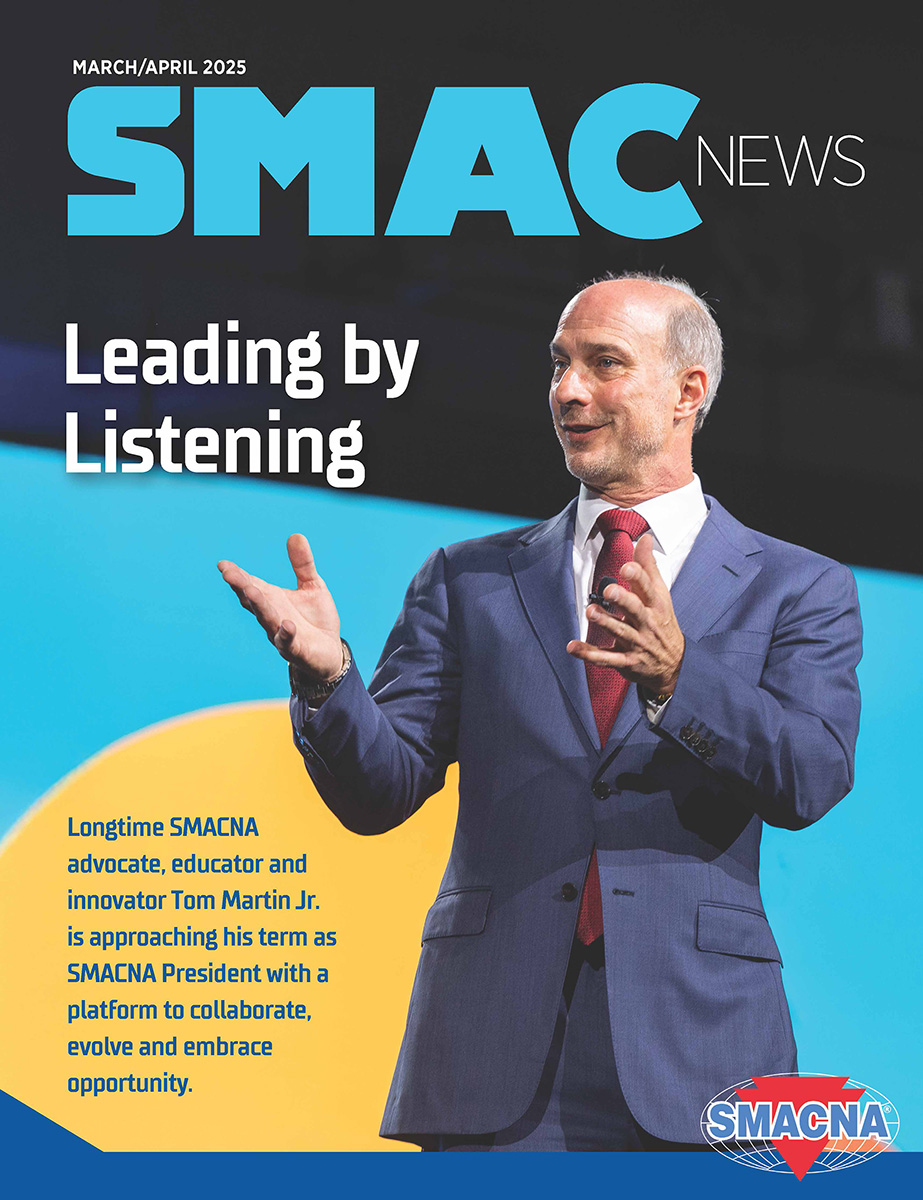

Leading by Listening

Longtime SMACNA advocate, educator and innovator Tom Martin Jr. is approaching his term as SMACNA President with a platform to collaborate, evolve and embrace opportunity.

Navigating Uncertainty: A Call for Caution and Collaboration Amid Political and Economic Shifts

“May you live in interesting times.” It is an old quote, often expressed as an ancient curse from China.

Residential: How To Build a Stronger Company Culture

HVAC and sheet metal contractors must go beyond the poster of values on the wall to truly improve their company cultures.

Safety First: SMACNA Sponsorship Opportunity & Safety Awards

SMACNA's Safety Sponsorship will send one member to the 2025 NSC Safety Congress & Expo in Denver, Colorado, on Sept. 15–17, covering up to $5,000 in travel expenses.

Securing Your Business Legacy: Why ESOPs Offer a Smarter Succession Strategy

Succession planning is an often overlooked aspect of many small and medium-sized businesses, leaving owners scrambling to make decisions without sufficient time to explore all available options.

SMACNA Launches New Website: A Game-Changer for Contractors

Designed for efficiency and clarity, the new SMACNA site delivers a modern, user-friendly experience that puts members first.

SMACNA Releases Major Updates to Seismic Restraint and Industrial Duct Construction Manuals

New editions introduce expanded bracing options, updated sizing tables and enhanced duct design capabilities.

Tariffs and Trade Uncertainty: What SMACNA Contractors Need to Know

The latest wave of tariffs is sending ripples of uncertainty through the construction industry, and sheet metal and HVAC contractors are bracing for significant cost increases.

The Future of HVACR Innovation Unfolds in Orlando

The world’s largest HVACR event brought together over 50,000 industry professionals for a powerhouse showcase of innovation, education and networking.

The Power of Emotional Intelligence in Leadership

Leadership is often framed as a matter of logic, decision-making and strategy.

Welcome New SMACNA Members