HVAC: Understanding Refrigerant Transitions

What HVAC contractors need to know about these important changes.

The HVAC industry is standing at the edge of a major shift — one that will change the way contractors handle refrigerants, service equipment and train technicians. The transition to low-global-warming-potential (GWP) refrigerants isn’t just a suggestion; it’s a reality driven by regulatory mandates.

The HVAC industry is standing at the edge of a major shift — one that will change the way contractors handle refrigerants, service equipment and train technicians. The transition to low-global-warming-potential (GWP) refrigerants isn’t just a suggestion; it’s a reality driven by regulatory mandates.

“The industry has known this was coming for years, but now it’s here,” says Paul Dombrosky, Refrigerant Manager for Service Operations at CHVAC North America. “Contractors who prepare now will be ahead of the curve. Those who don’t will be scrambling when these refrigerants become the standard.”

Here’s what HVAC contractors need to know and how they can get ahead of the coming refrigerant shift.

Why the Transition Is Happening

At the heart of the change is the American Innovation and Manufacturing (AIM) Act, which mandates a phasedown of hydrofluorocarbons (HFCs) in favor of lower-GWP refrigerants. This legislation aligns with the global Montreal Protocol Kigali Amendment, which sets aggressive reduction targets for HFC production and consumption.

“The AIM Act isn’t a future problem; it’s happening now,” Dombrosky says. “As of Jan. 1, common refrigerants like R-410A, R-404A and R-134a are no longer permitted in new equipment.”

That means contractors need to adapt to A2L refrigerants, which are mildly flammable but significantly better for the environment.

How This Affects HVAC Contractors

Contractors must prepare for changes in:

New equipment installations: In 2025, most new air-conditioning and refrigeration systems must use low-GWP refrigerants.

Servicing existing systems: While current HFC-based systems can still be repaired, reclaimed refrigerants will be required for servicing by 2028.

Component compatibility: New refrigerants mean new components, tools and safety measures.

“If you’re still using legacy refrigerants, your costs are going to skyrocket,” Dombrosky warns. “Refrigerant supply will be tighter, and prices will continue to rise. Contractors need to have a long-term game plan.”

After understanding the background on why the change is happening and the related business impacts, the next step is taking action. HVAC contractors can follow these guidelines from Dombrosky to ensure a smooth transition.

1. Train Your Technicians on A2L Refrigerants. One of the biggest changes with the new refrigerants is their mild flammability, which requires updated safety protocols.

“Technicians can’t treat A2Ls the same way they did R-410A,” Dombrosky says. “They need to understand proper handling, leak detection, ventilation and evacuation procedures.”

HVAC businesses should invest in A2L certification courses to ensure their teams are trained before these refrigerants become widespread.

2. Upgrade Tools and Equipment. Contractors will need A2L-compatible tools, including:

- Refrigerant recovery machines specifically designed for A2Ls

- Manifolds and gauges that can handle the new pressure and flammability concerns

- Leak detectors calibrated for A2L refrigerants

- “Your existing manifolds and scales will still work, but some digital manifolds may need firmware updates,” Dombrosky notes. “And leak detection becomes even more critical with A2Ls.”

3. Plan for Rising Refrigerant Costs and Supply Constraints. With the phase down of HFC production, contractors should expect supply shortages. Some states, like California, New York and Washington, may even restrict refilling with virgin refrigerants altogether.

“This isn’t just about new installations; it’s about how you’re going to service existing customers,” Dombrosky says. “If you don’t have a plan for refrigerant recovery and reuse, you’re going to be at a disadvantage.”

He recommends that contractors:

- Stock up on reclaimed refrigerants to prepare for rising costs.

- Educate customers about retrofit options for existing systems.

- Adopt leak prevention practices to extend system life and reduce refrigerant waste.

4. Understand the New Compliance Deadlines. Key transition dates for these refrigerant changes include:

- Jan. 1, 2025 — R-410A, R-404A, and R-134a banned in new equipment.

- Jan. 1, 2026 — VRF (Variable Refrigerant Flow) systems must switch to low-GWP refrigerants.

- Jan. 1, 2028 — Reclaimed refrigerants required for servicing existing systems.

“Regulations will only get stricter,” Dombrosky says. “The sooner contractors align with these changes, the smoother the transition will be.”

Don’t Wait Until It’s Too Late

While the refrigerant transition presents challenges, it also creates opportunities for contractors to lead the industry forward. Those who invest in training, upgrade their tools and educate their customers will have a competitive edge over those who wait until the last minute.

Published: April 30, 2025

IN THIS ISSUE

A Hub for Cutting-Edge Technology & Collaboration

Attendees Get Hands-On During the Sheet Metal JATC Local 105 Tour at the 2025 MEP Innovation Conference.

Architectural: Working in the Red Zone

A Michigan contractor scored when the company made and installed a hotel's architectural panels just in time for the 2024 NFL draft.

HVAC: Understanding Refrigerant Transitions

What HVAC contractors need to know about these important changes.

Industrial: Aiming High

Matherly Mechanical’s ventilation project at an Oklahoma City Air Force base was critical to ensuring that work servicing military aircraft continued uninterrupted.

JATCs Assess the Impact of President Trump’s Executive Order Ending Affirmative Action and DEI Programs

On Jan. 21, 2025, President Trump signed Executive Order 14173, “Ending Illegal Discrimination and Restoring Merit-Based Opportunity” (the “EO”).

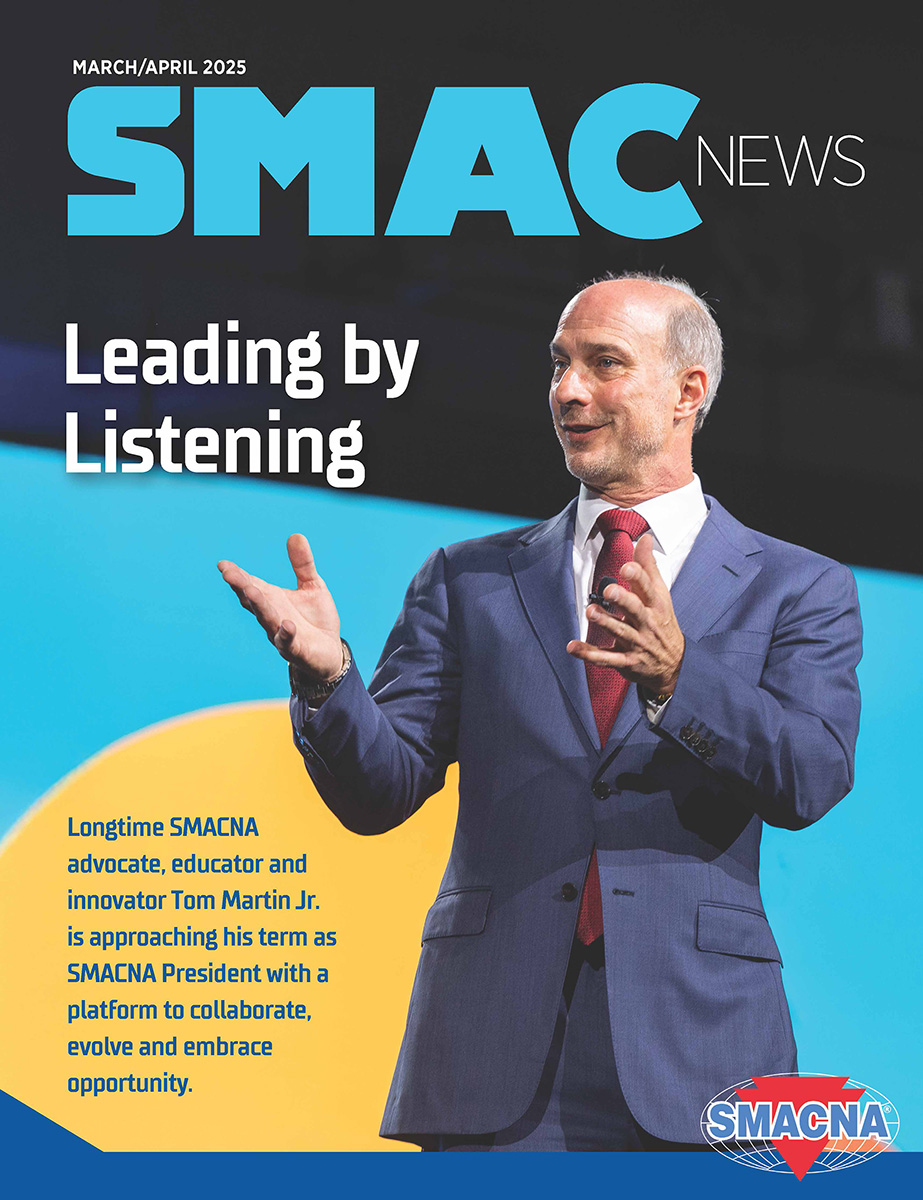

Leading by Listening

Longtime SMACNA advocate, educator and innovator Tom Martin Jr. is approaching his term as SMACNA President with a platform to collaborate, evolve and embrace opportunity.

Navigating Uncertainty: A Call for Caution and Collaboration Amid Political and Economic Shifts

“May you live in interesting times.” It is an old quote, often expressed as an ancient curse from China.

Residential: How To Build a Stronger Company Culture

HVAC and sheet metal contractors must go beyond the poster of values on the wall to truly improve their company cultures.

Safety First: SMACNA Sponsorship Opportunity & Safety Awards

SMACNA's Safety Sponsorship will send one member to the 2025 NSC Safety Congress & Expo in Denver, Colorado, on Sept. 15–17, covering up to $5,000 in travel expenses.

Securing Your Business Legacy: Why ESOPs Offer a Smarter Succession Strategy

Succession planning is an often overlooked aspect of many small and medium-sized businesses, leaving owners scrambling to make decisions without sufficient time to explore all available options.

SMACNA Launches New Website: A Game-Changer for Contractors

Designed for efficiency and clarity, the new SMACNA site delivers a modern, user-friendly experience that puts members first.

SMACNA Releases Major Updates to Seismic Restraint and Industrial Duct Construction Manuals

New editions introduce expanded bracing options, updated sizing tables and enhanced duct design capabilities.

Tariffs and Trade Uncertainty: What SMACNA Contractors Need to Know

The latest wave of tariffs is sending ripples of uncertainty through the construction industry, and sheet metal and HVAC contractors are bracing for significant cost increases.

The Future of HVACR Innovation Unfolds in Orlando

The world’s largest HVACR event brought together over 50,000 industry professionals for a powerhouse showcase of innovation, education and networking.

The Power of Emotional Intelligence in Leadership

Leadership is often framed as a matter of logic, decision-making and strategy.

Welcome New SMACNA Members