Stainless Spires Rise Above the River

Budde Sheet Metal Works crafts soaring eagle-wing spires, blending old-school expertise and next-gen training for Dayton’s New Law Enforcement Memorial that honors fallen officers.

Next spring, an 8-foot granite wall with extensive landscaping, trees, and paths will overlook the Miami River in Dayton, Ohio. The new $2-million Montgomery County Law Enforcement Memorial will commemorate 49 law enforcement officers who have fallen in the line of duty. Budde Sheet Metal Works of Dayton, Ohio, completed the first stage of the memorial this fall by installing five 30-foot stainless steel spires. “There's a concrete pad with a star design, and these spires sit at every point of the star,” says Michael Worley, Project Manager for Budde Sheet Metal Works.

Next spring, an 8-foot granite wall with extensive landscaping, trees, and paths will overlook the Miami River in Dayton, Ohio. The new $2-million Montgomery County Law Enforcement Memorial will commemorate 49 law enforcement officers who have fallen in the line of duty. Budde Sheet Metal Works of Dayton, Ohio, completed the first stage of the memorial this fall by installing five 30-foot stainless steel spires. “There's a concrete pad with a star design, and these spires sit at every point of the star,” says Michael Worley, Project Manager for Budde Sheet Metal Works.

The Law Enforcement Memorial Association selected the local architectural firm Earl Reeder Associates to bring the memorial to life, and Earl Reeder engaged Budde Sheet Metal Works early. “We have done a couple of projects for him in the past,” Worley says, “so he came to us with a concept. This was before they completed the funding for this project, probably a year and a half ago.”

|  |  |

Budde had a prior relationship with the architect, so he is familiar with their valuable skill set. “We have an in-house CAD design team,” says Candice L. Budde, President of Budde Sheet Metal Works. “So we have a history of success with these kinds of projects.” The head of the CAD and IT department has been with the contractor for 30 years. “The structural engineer and the planning committees bring the project to us with their concept, then we develop the print, the blueprints, and the drawings. They give us free rein to develop it and prepare the fabrication drawings, as long as we stay within the structural engineers' guidelines. That is unique to what we do. Not many sheet metal companies in the area can do that.”

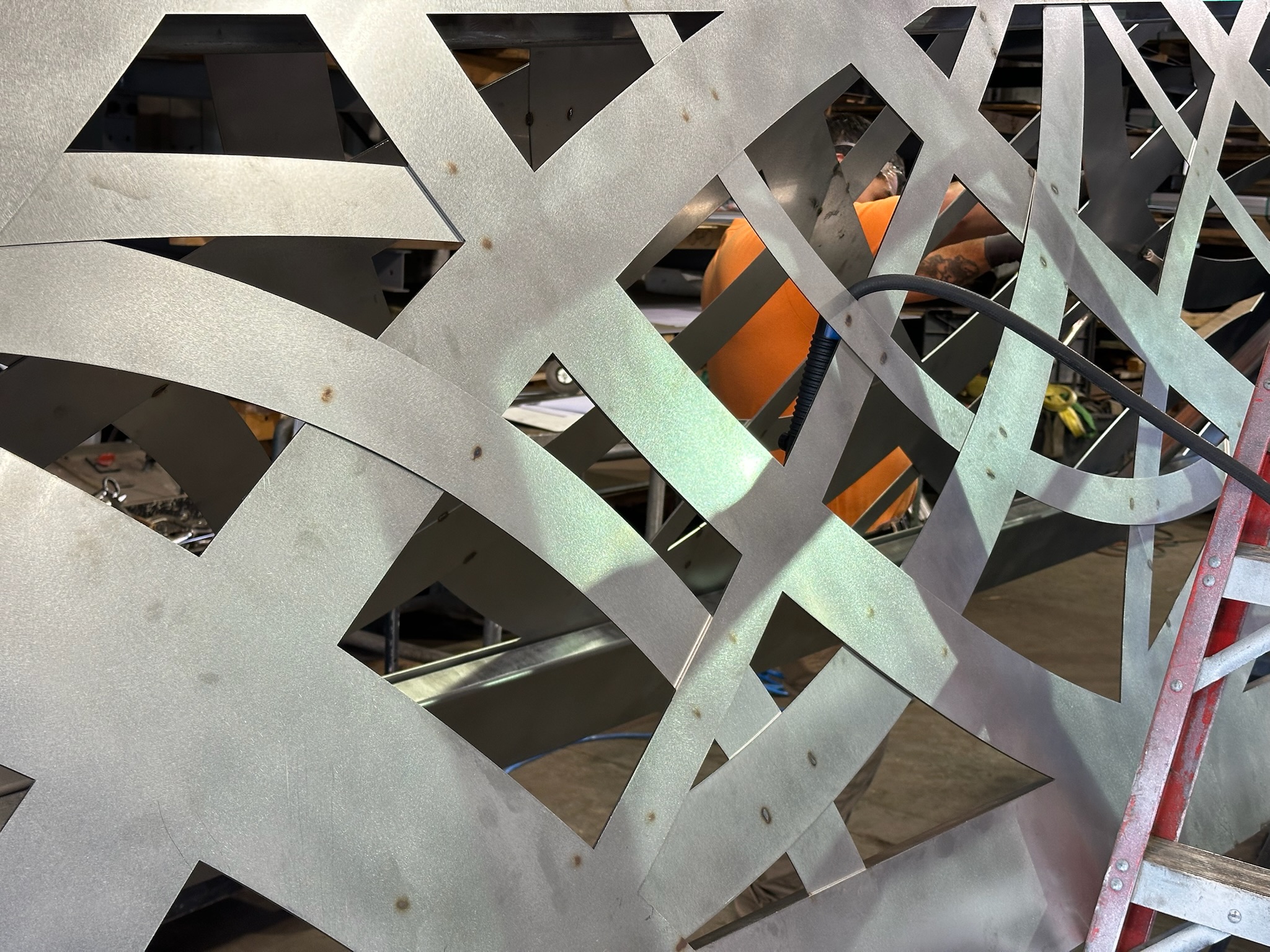

Budde’s team worked closely with the customer to design the cutouts in the 10-gauge steel. “You'll notice weaving in the spires,” Worley says. “That's a neat aspect that gives this project a bit of a 3D look.” Budde cut the spires on their 4000-watt Trumpf laser, then wove lighter-gauge ribbon in between the cutouts. “The woven details were the biggest issue as far as designing. They required significant planning and back-and-forth with the customer.

Budde’s team worked closely with the customer to design the cutouts in the 10-gauge steel. “You'll notice weaving in the spires,” Worley says. “That's a neat aspect that gives this project a bit of a 3D look.” Budde cut the spires on their 4000-watt Trumpf laser, then wove lighter-gauge ribbon in between the cutouts. “The woven details were the biggest issue as far as designing. They required significant planning and back-and-forth with the customer.

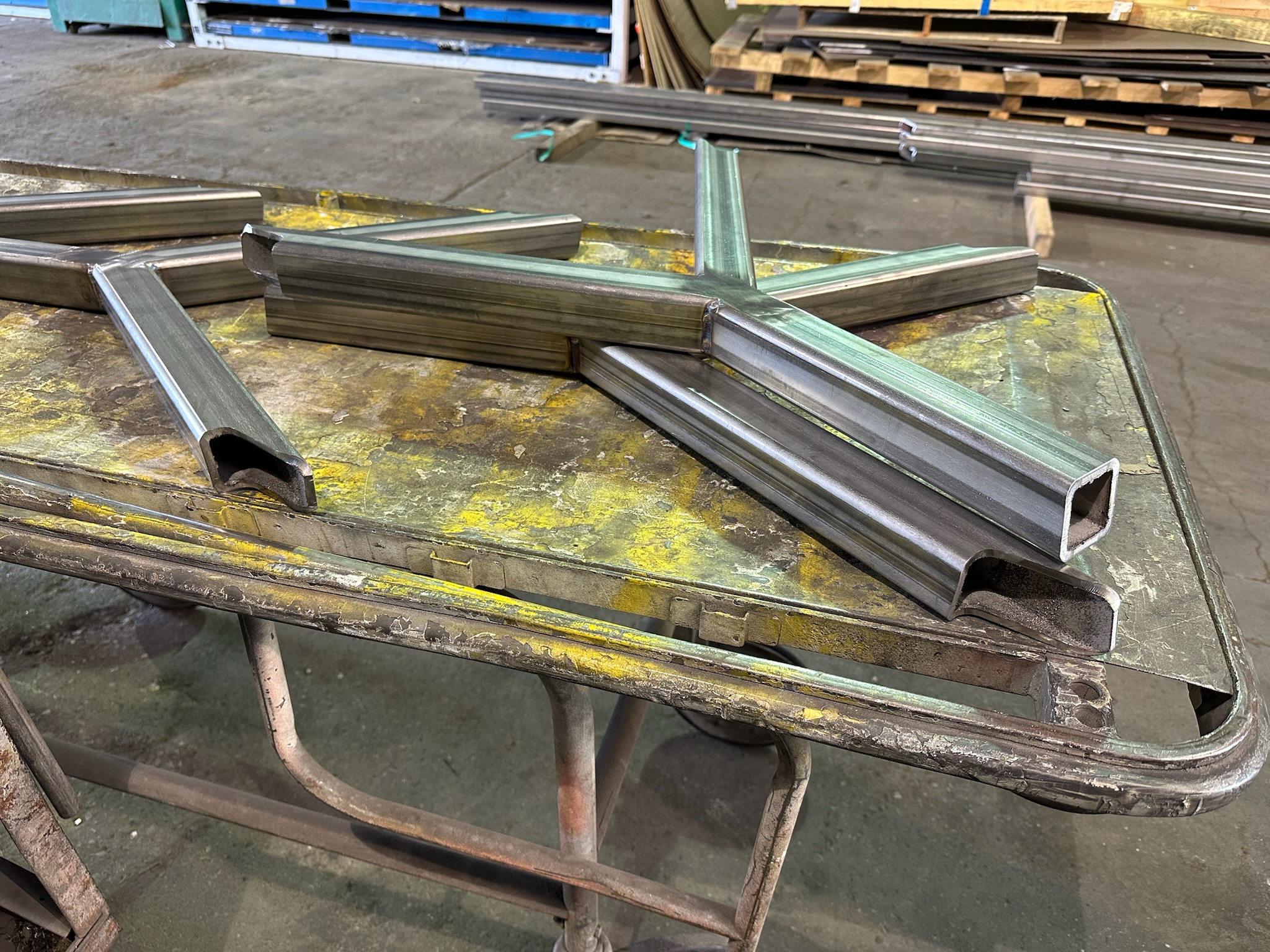

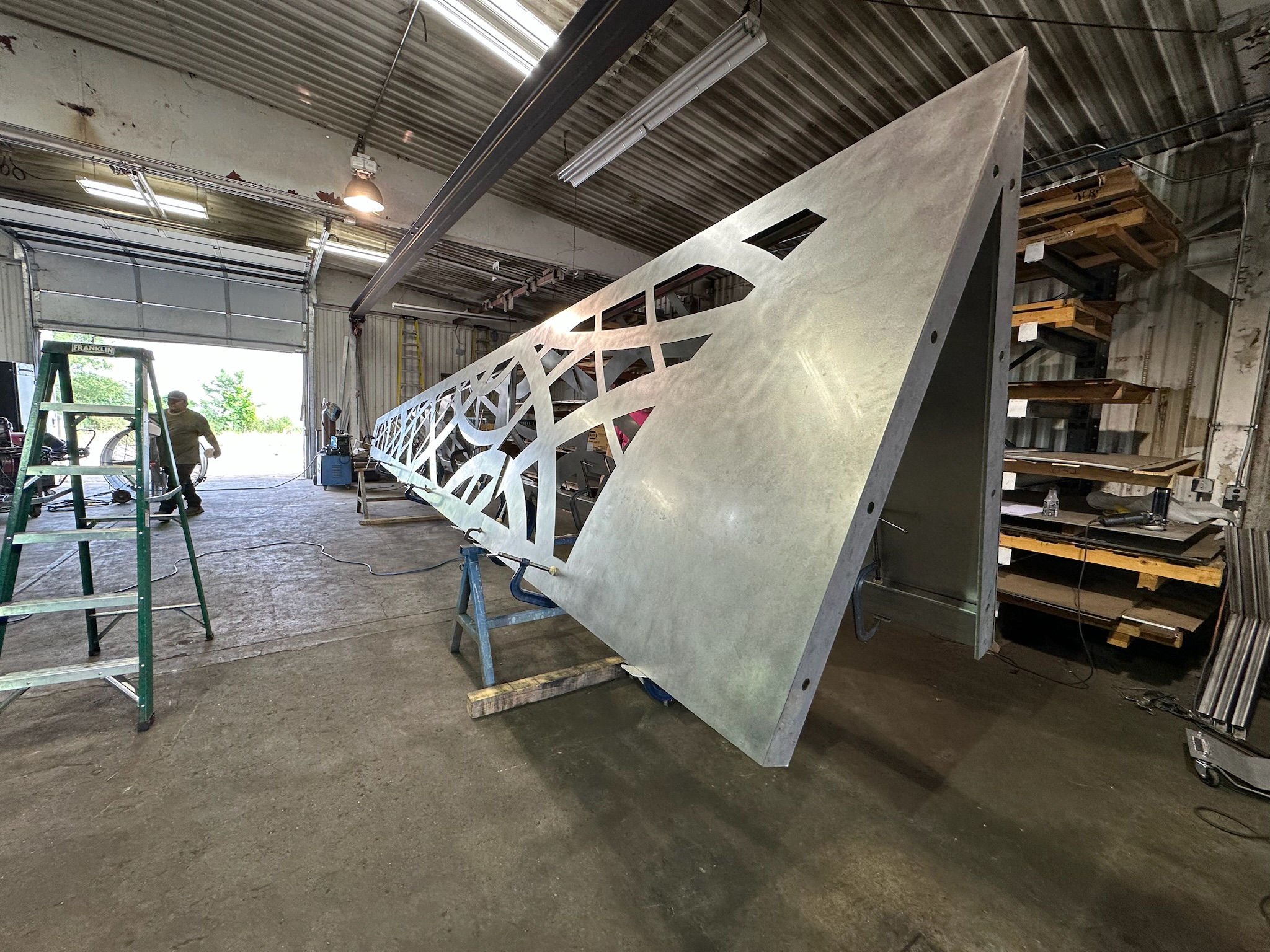

The spires represent the eagle’s wings, which added another complication. “They may look straight in the pictures, but there's a slight curvature to the spires,” Budde says. “To get the heavy-duty structural tubing to hold that curvature and to be consistent, the team treated the parts as puzzle pieces. They had to make sure all the pieces fit in correctly to follow the same curvature for the final project.”

To construct the spires, Budde purchased about 500 feet of structural tubing, both square and rectangular, and the team did all fabrication in the shop. They used 30 sheets of 10-gauge 304 stainless steel for the spires and five sheets of 16-gauge reinforced panels for the ribbons. Each panel was carefully selected to ensure a consistent appearance. “You’re using sheets of metal from different lots, so you want to match the coloring of the metal to make sure that it looks good,” Budde explains. “It's a public piece, so you can't just put it out there. You have to make sure that it's pristine, that your welds are hidden and cleaned up correctly and that it looks great. The finish is very important.”

The five completed spires weigh 1,800 pounds apiece for a total of 9,000 pounds of stainless steel. “The guy who led the installation has done bigger projects, heavier projects, before, so he knows how to use hoisting and cranes and how to move the material to get it in place the way he wants to,” Budde says. “He knows how to manipulate the metal and move it around to get the desired effect. It's not easy when it's big, cumbersome pieces. Using the correct rigging and moving methods played an integral part in our success.”

The five completed spires weigh 1,800 pounds apiece for a total of 9,000 pounds of stainless steel. “The guy who led the installation has done bigger projects, heavier projects, before, so he knows how to use hoisting and cranes and how to move the material to get it in place the way he wants to,” Budde says. “He knows how to manipulate the metal and move it around to get the desired effect. It's not easy when it's big, cumbersome pieces. Using the correct rigging and moving methods played an integral part in our success.”

Budde’s experienced team members took the opportunity to train the next generation of craftspersons. “He had some of the younger guys on his team, and he did a great job of teaching them and showing them how to do this work,” Budde says. “This was a great project for training because it was so fabrication-intensive.”

“Everyone in our shop touches almost every project because of how we do the fabrication process,” Budde says. But four dedicated workers completed the bulk of the spire fabrication over eight weeks, totaling 900 shop hours. Three workers handled the actual installation on site, which took another two days, or about 100 more hours, for a final total of 1,000 hours. From fabrication to installation, Budde devoted 4.5 months to the project.

“Everyone in our shop touches almost every project because of how we do the fabrication process,” Budde says. But four dedicated workers completed the bulk of the spire fabrication over eight weeks, totaling 900 shop hours. Three workers handled the actual installation on site, which took another two days, or about 100 more hours, for a final total of 1,000 hours. From fabrication to installation, Budde devoted 4.5 months to the project.

“Anytime we successfully complete a project, I think everybody is satisfied, especially when it’s a very custom piece like this,” Worley says. But the Montgomery County Law Enforcement Memorial is an extra source of pride. Budde’s work is visible for miles along the river, and television crews filmed the installation crew for local news shows. “It’s going to be up there for decades, and our kids are going to see it. We will always be able to point to this memorial and say, ‘Hey, I had a hand in that.’

Published: January 12, 2026

IN THIS ISSUE

A Journey Built on Opportunity: SMACNA’s New President Looks Ahead

Aloha, everyone. It means the world to me to serve as your 2025-2026 SMACNA National President.

Appeals Court Upholds Minnesota's Construction Worker Misclassification Law

On Oct. 24, the U.S. Court of Appeals for the Eighth Circuit issued a decision that should be viewed as a meaningful victory for responsible union construction contractors.

Breaking Records, Building Opportunities

Industry leaders gather to strengthen ties and shape the future of the HVAC and sheet metal trades.

Flying High Again

SMACNA member W.G. Tomko’s work on the redesigned mechanical systems at Pittsburgh International Airport was key to the $1.7-billion renovation project.

Forging the Future of Industrial Sheet Metal

Family-founded and future-focused, Vidimos Inc. stakes its reputation on precision, flexibility and a commitment to craftsmanship.

Navigating Tariffs, Tax Incentives, and Workforce Priorities

On going legislative developments and regulatory actions at the federal level continue to shape the competitive landscape, costs and project opportunities for HVAC and sheet metal contractors.

On the Brink of Change

How one residential HVAC contractor has been preparing for the A2L refrigerants transition.

On the Front Lines of Policy

Congressman Ed Case talks defense, dysfunction and the future of America’s builders.

P1 Construction Sets New Benchmark in Construction Safety with Dual Innovation Programs

SMACNA’s 2025 Safety Innovator of the Year creates a safer, more supportive culture for workers.

Raising the Bar in Brazil

Inside SMACNA Brazil’s mission to bring quality HVAC and cleaner air to the forefront.

Stainless Spires Rise Above the River

Budde Sheet Metal Works crafts soaring eagle-wing spires, blending old-school expertise and next-gen training for Dayton’s New Law Enforcement Memorial that honors fallen officers.

The Majority of SMACNA Members Need a CTO

Conferences across construction and fabrication are full of talk about analytics, metrics and KPIs.

The ROI of AI in Construction: A Financial Perspective

Contractors are increasingly presented with AI-powered tools marketed to boost efficiency and reduce risk.

Uncertainty is the New Normal

Economist Rebecca Patterson warns that tariffs will rise and AI will reshape work as the economy enters uncharted territory.

Welcome New SMACNA Members

When the Sky Isn't the Limit

Colonel Nicole Malachowski shows SMACNA how courage, change and gratitude can take leaders further than altitude ever could.